Making Mukena From Shallots Peel (Allium Ascolonium L) As Staining Satin Fabric Using Mordant Lime

Onions Peel as a Natural Dyes

Parts of the plant that can be used for natural dyes of skin, twigs, leaves, roots, flowers, seeds or sap. Natural Dyes are color substances obtained from nature / plants either directly or indirectly. Each plant contains a natural source, because it contains natural pigments. This potential is determined by the intensity of the resulting color and depends heavily on the type of coloring matter that exists.

Coloring matter is a substance that determines the color direction of natural substances, is an organic compound contained in the source of natural color substances. Old shallots have good shallot skin and contain a lot of tannins. So it has the potential to produce color after the extraction process. Shallot skin is usually used for dyeing the manufacture of pindang eggs, decorators of rooms formed by flowers and as plant grower. In addition, shallot skin can be used as a natural dye on textiles, by way of red onion skin boiled for a long time will produce a brownish orange color. This result will be used as the main dye material to make mukena.

Satin Fabric

Satin is a type of silk satin fabric that is woven using filament fiber technique so that it has the characteristic shiny surface and klinyir-klinyir. The inside or back of the satin surface is otherwise not slippery and not shiny.

Lime as mordant

The purpose of mordant administration is to increase the absorption of fabrics against natural color substances. The use of natural dyes for textiles requires mording or initial treatment before the use of dyes on materials. Previously the mordies used were mordies containing chemicals such as chrome, lead, copper, zinc and iron. Mordy for natural dyes has been developed that do not contain chemicals and are environmentally friendly such as orange citrun, lime, vinegar, belching (salpenfer), pijer (borax), alum(alum), sugar cubes, java sugar (aren), cape (ijzer vitrloll) poetry (coper sulfate), drops (sugar cane stroop or melasse) lime water, tape (ketela tape, sticky rice tape), banana klutuk, guava leaves as an alternative used as mordantt on textile dyes. mordant is a substance used in the dyeing process so that the color absorbed into the fabric is stronger and can be used before or after the dyeing process.

Based on the abundant content in limes it is not surprising that a potent lime blocks tonsils, malaria, ambient, shortness of breath, influesa, cough. Based on its chemical content and existing benefits, lime can be used as a mordant or color-generating substance in coloring. The solution of lime is obtained by squeezing. Sebalum squeezed, lime washed first, split transversely into 2 parts then squeezed using an orange squeeze. Lime juice can be used after mixing with clean water.

Satin Fabric Coloring

The process of coloring or dyeing is the process of combining color substances with fibers and fiber results have a durable color. Coloring with natural coloring substances should use materials from natural fibers, although it does not cover the possibility to use artificial fibers. Fabrics that will be dyed with natural color substances must go through the scoring process first. The process of bathing on a satin cloth is called degumming and dissolved with a weak alkaline, such as a soap solution, at a temperature of 700 C for 1 to 2 hours. The purpose of the degumming process can be to remove kanji or dirt on the fabric, so that the absorption of color on the fabric can be evenly distributed.

Natural color substances to be used in the dyeing process must have the following conditions :

- Easily soluble in solvents

- Easy entry into materials

- Stable against materials

- Has a chromofor cluster

- Has a cluster of affinity for textile fibers ( auxsochrom)

The coloring of the fabric is done in various ways, depending on the type of color substance on the fiber to be colored. The process of coloring with shallot skin extract is classified in direct dyes, in addition to the process of working on its own also takes a long time. The satin fabric is not resistant to heat so the staining process uses cold dyeing, a solution of shallot skin extract that is ready to be left dinggin then the fabric is dipped in shallot skin extract for 30 minutes. Natural dyes used since ancient times and some still used today have advantages and disadvantages are :

1. Advantages of Natural Color Substances

a. This natural dye is free from chemicals so it is far from environmental pollution.

b. Plants used as dyes can be obtained from the surrounding environment so as to save costs.

c. By using color substances indirectly participate in preserving the plant type

2. Weakness of Natural Color Substances

a. Does not have color standards

b. Low fastness

c. The process of getting colors is difficult

d. The process for coloring is difficult

e. Limited color collection

Read more Scientific Papers here and here

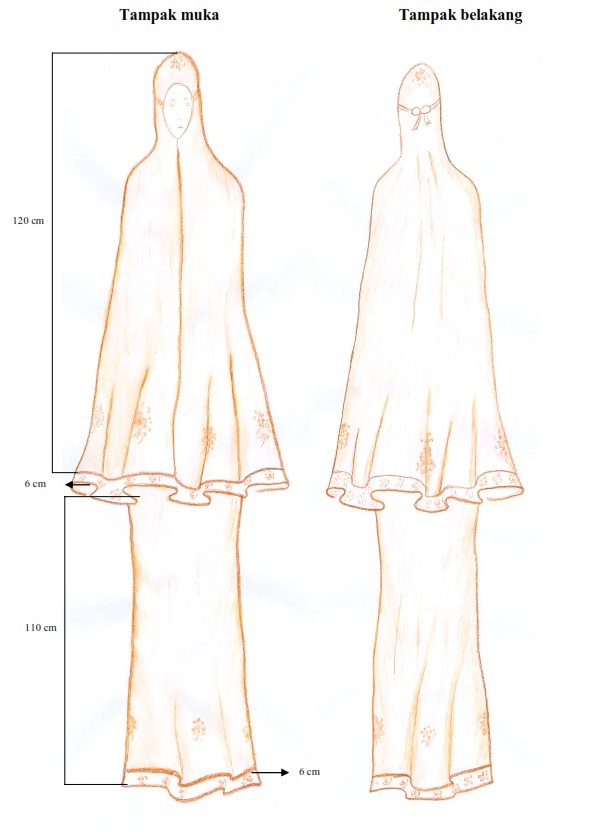

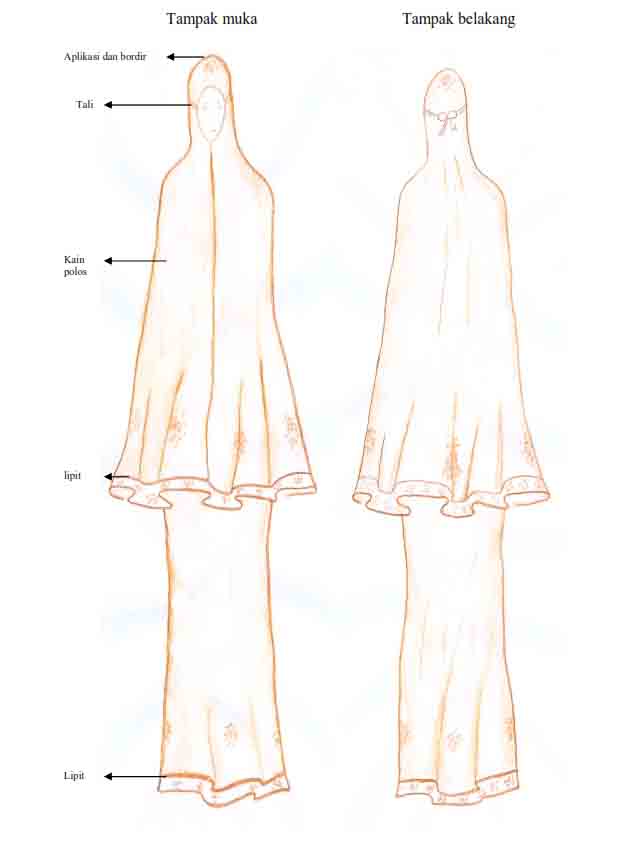

Mukena is a sewn sheath (usually white) to cover the aurat of Muslim women during prayer (Departemen Pendidikan Nasional 2005: 760). For now mukena has a wide variety of color fariasis or models, mukena is made not only using white fabric, but using other colors that are not conspicuous. On the result of coloring of the shallot skin extract will be made in the form of mukena. The steps that must be prepared in making mukena are :

Mukena Design

Production Design 1

Setting Up Tools

1. Sewing machine

2. Needles and scissors

3. Sewing Thread

4. Pencil for drawing brothels

5. Pattern paper

6. Elastik

7. Carbon and chalk sewing

Setting Up Components

Satin fabric that has been dyed with shallot skin extract and batik cloth for decoration.

Setting Up Size and Pattern

SIZE

Mukena length : 120 cm

Skirt length : 120 cm

Waist band : 65 cm

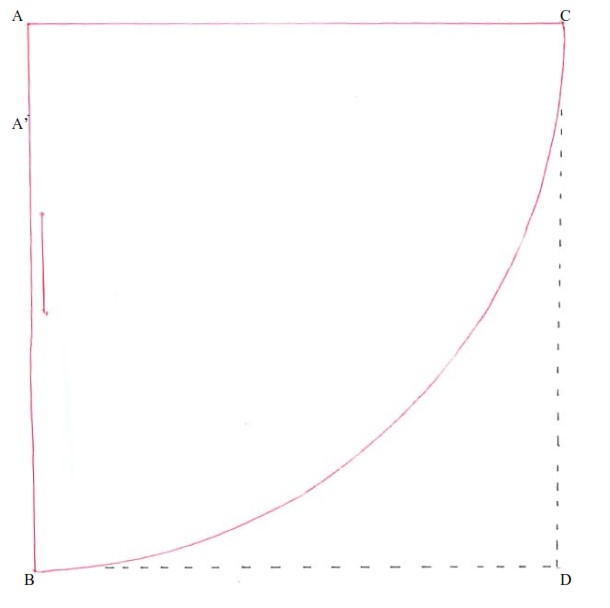

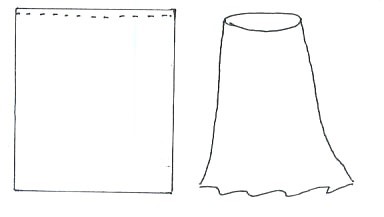

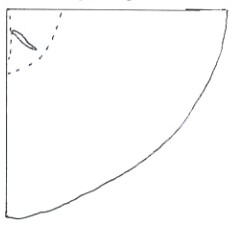

MUKENA PATTERN

Scale 1:8

Top pattern

A-B : Face length : 120 cm

A-A’ : 27 cm

A-C : B-D : Mukena length : 120 cm

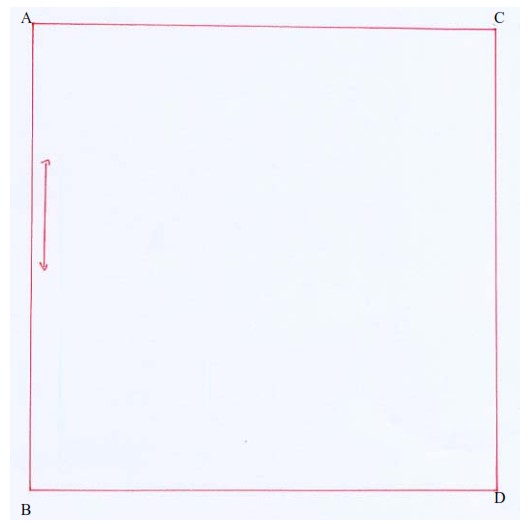

Mukena Skirt Pattern

Scale 1:8

Description

A-B : Skirt Length = 120 cm

A-C : Skirt Width = 100 cm

C-D : A-B

Prepared Components

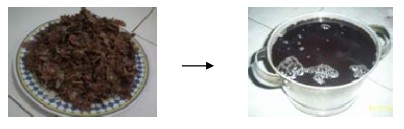

A. Shallots skin

An old type of shallot skin. To make mukena from shallot skin extract it takes 250 gr /l and two liters of boiled water to be used as 1 liter of water.

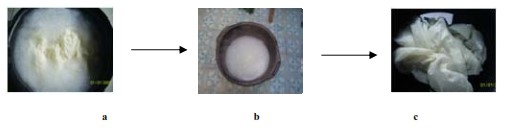

Shallots peel

b. Satin fabric measuring 15 X 15 cm (for pre-experimentation). Satin fabric used for mukena requires 3 m fabric

Satin fabric

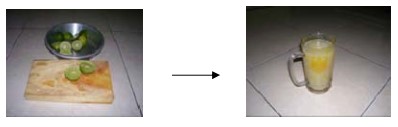

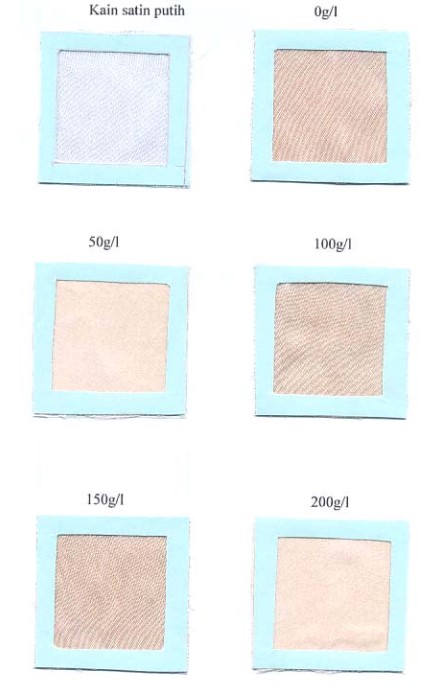

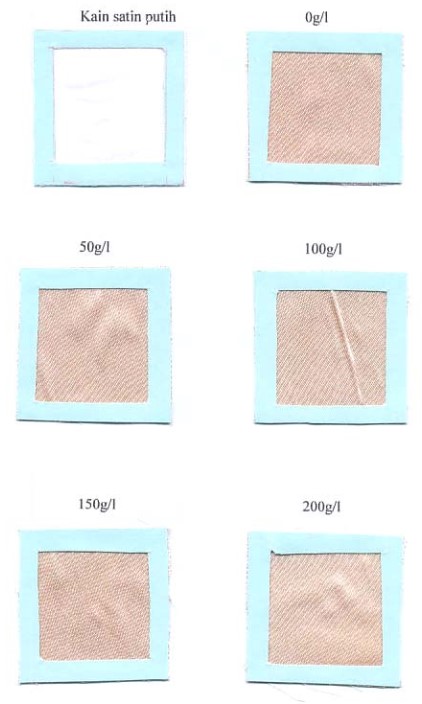

c. Lime with mordant solution concentration solution 50 g/liter, 100 g/liter, 150 g/liter, 200 g/liter.

Tray

Steps to Create Mukena

Preparation of extraction of shallot skin into natural dyes

1. Tools

a. Scales

b. Measuring glass

c. Baskop/ bucket tub

d. Ringing cloth

e. stirrer

2. Ingredients

a. Shallots skin

b. Water

3. Extraction of shallot skin

a. Shallot skin cleaned

b. Weighs 250 g/l shallot skin

c. Boil the shallot skin until it removes color for approximately 1 hour

d. Filter the results of shallot skin stew on a filtering cloth

e. Shallot skin extract ready for use as dye

4. Satin washing

1. Tools

a. The pan is used as a water boil and makes shallot skin extract

Stove and Pan

b. The stove is used as a water heater

c. Stirrer to stir soap.

Mixer

d. Buckets used for cloth immersion

Buckets

e. Bath soap, for washing satin fabric

soap

f. Thermometers are used to measure the temperature of immersion or washing of fabric to be colored.

Thermometer

2. Ingredients

a. Cain

b. Water

3. Washing

A. Prepare 1 liter of water at 70o C with a solution of 1 g into it until foamy, moisten the satin cloth with regular water, drain and soak with soapy water

B. After soaking 30 minutes the satin cloth is rinsed with regular water until clean

C. After rinsing the satin cloth directly sliced without being squeezed, dried in the shade

Mordanting process

1. Tools

a. Plastic pot

b. Clock

c. Fabric clamps

d. Filter

2. Ingredients

The materials used for the mordantting process are cold water satin fabric and lime solution with a concentration of 0g/liter, 50g/litre, 100g/litre, 150g/litre, 200g/litre.

3. Procedure of making mordant solution

A. Lime is cleaned by washing, then cut into 2 parts then squeeze the water using a filter

B. Weigh orange water according to the concentration to be used as mordant

4. Mordantting process procedure

The mordantting process procedures are:

A. Preparing tools and materials

B. Put a solution of lime mordant on the supplied tray

C. Put the satin cloth on a solution of lime mordant for 30 minutes

D. The cloth is lifted and dried by the wind it in the shade.

Dyeing Process

1. Tools

A. Plastic pots/buckets

b. Clock

c. Fabric clamps

d. Filter cloth

e. Filter

2. Ingredients

A. Shallot skin extract

B. Dimordant satin fabric

c. Cold water

3. Dyeing procedure

A. Preparing tools and materials

B. Preparing cold water on a bucket

C. Put a solution of shallot skin extract on pot / bucket d. Wet the cloth first with water to taste

E. Soak the cloth on the shallot skin extract for 30 minutes

F. The fabric is lifted with tongs and the cloth is dried by the wind – wind it in the shade

Steps to Make Mukena, Extra Dyeing Of Shallot Skin With Lime Mordant

1. Preparing tools and materials

A. Tools: bucket, clock, cloth clamp, filter cloth, filter, scale, measuring glass, stirrer, pot, stove, thermometer to measure water temperature when washing fabric.

b. Material: Bath soap, for washing satin cloth, shallot skin, lime, satin cloth, water used for mordating process.

2. Preparing satin fabric with a size of 15 x15 cm as much as 10 sheets.

3. Degumming satin fabric

A. Prepare 5 liters of water with a temperature of 700 C and dissolve 1 gr of bath soap into the water until it is virtuous.

B. Moisten the satin cloth with water first with regular water ,drain and soak for 30 minutes.

C. After rinsing the satin cloth rinsed with regular water then sliced without being squeezed, then dry in the shade.

4. Extraction of shallot skin

A. The shallot skin is given from dirt, then washed and drained until dry.

B. Prepare 2 liters of water to boil the skin of shallots. The extrasition is to boil the shallot skin for 1 hour until the water contains about 1 liter of shallot skin when the skin is stirred to be evenly distributed.

C. After it is filtered

D. The solution of shallot skin extract is ready to be used for staining.

5. Preparing lime mordant

A. The lime is washed first, divide the lime into 2 equal parts, and squeeze the lime using a filter.

B. Orange juice istakar according to the size of 0g/liter, 50g/litre, 100g/litre, 150g/litre, 200g/litre.

C. Mix each concentration with 1liter of stirring water until evenly combined. d.Measured lime extract ready for mordating

6. Mordantting

A. Each mordant with different concentrations is poured into the tray.

B. The satin cloth is soaked in mordant for 30 minutes.

C. Lifted and winded to dry

7. Coloring

Put the solution of shallotskin into the tray. Put the fabric to be in the tray, before the fabric is moistened with regular water first with regular water, then put the satin cloth in the tray for 60 minutes.

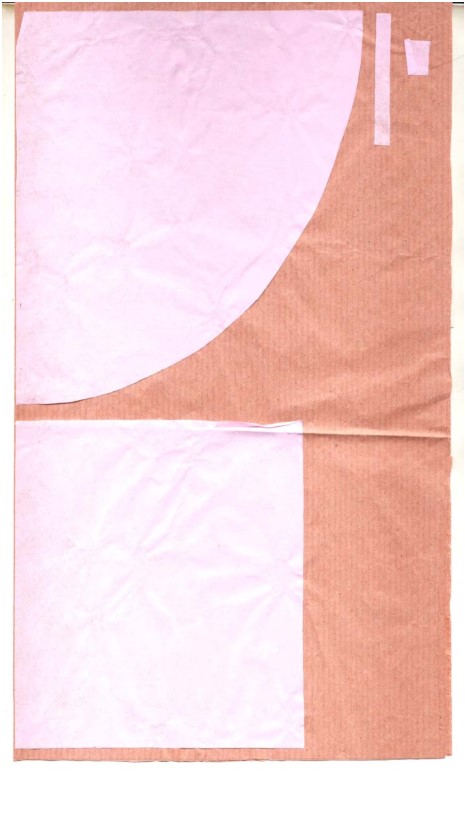

How to Make Mukena After Dyeing Process

1. Create the design

2. Create a small pattern

3. Designing materials

4. Create a Large Pattern

5. Preparing materials

6. Cutting and sewing

Steps in sewing

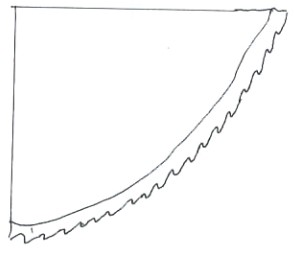

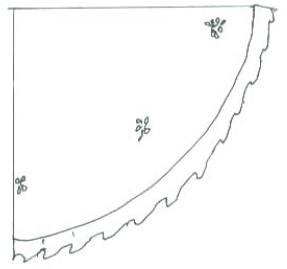

1. Sewing the sides of the mukena skirt

2. Sewing the waist and installing rubber at the waist

3. Sew the lining on the top of the mukena and attach the strap

4. Sewing the middle of the face mukena

5. Sewing batik fabric that is 5 cm wide on the bottom of mukena

6. Embroidering the ornaments on the mukena and on the mukena skirt

Mukena Extra Dyeing Results of Shallot Skin With Lime Mordant

The fabric of coloring by using shallot skin extract with lime mordant for once dyeing among others is:

The fabric of coloring using shallot kilit extract with lime mordant for twice dyeing are:

The experiment process resulted in a good color head using lime mordant with a concentration of 100 g/l and dipped with shallot skin extract which will then be made mukena. Coloring to make this mukena using 100g/l mordant, this is because the concentration of the mordant produces a softer color compared to the colors of the dyeing of other concentrations. In the process of staining satin fabrics are many obstacles one of them is weather conditions that do not support and fabrics that are too long so it is difficult when doing coloring. So that the fabric becomes dirty, after washing against the mukena the color of the fabric becomes changed this is caused by the poor level of misfortune and coloring absorbed by the material can not enter perfectly into the material or color only sticks to the surface of the fabric, so that the fabric has an ugly level of misfortune. Since the material is possible not 100% catun or natural fibers and this immersion is done with warm water.

Making Mukena Price Plan

|

No |

Item name |

Unit price |

Unit |

Price |

|

1 |

Satin fabric |

Rp 25.000; |

4.5 m |

Rp 102.500; |

|

2 |

Yarn |

Rp 1.800; |

1 buah |

Rp 1.800; |

|

3 |

Plastic |

Rp 6.000; |

60 cm |

Rp 4.000; |

|

Total |

Rp 108.300; |

|||

Mukena Results With Dyeing Of Shallot Skin Extract With Lime Mordant

CONCLUSION

The results of this experiment can be taken in the following conclusions:

1. Shallot skin can be used as dye material in satin fabric staining process

2. There is a difference in the quality of the color on the satin fabric dyed with extra shallot skin with different concentrations of lime mordant and no difference in the quality of the kelunturan on the satin fabric dyed with extra Shallot skin with different lime mordant.

Some of the suggestions found from this ecxperimen are, there should be advanced ecxperimen using esktrak-extracts and other types of ingredients to obtain better desecration results.

Read more Scientific Papers here and here

BIBLIOGRAPHY

Adhi Kusumastuti. 2007. Penyempurnaan Tekstil. Semarang: UNNES Bawang merah.

Departemen Pendidikan Nasional. 2005 Kamus Besar Bahasa Indonesia. Jakarta:Balai Pustaka.

Dekranas. 1999. Seminar Bangkitnya Warna-Warna Alam. Yogyakarta:DEKRANAS

Gombolo.1994 Diklat Kuliah Penggantar Pencelupan. Yogyakarta: Jurusan Teknologi Tekstil FTI UII

Jumaeri. Dkk. 1977. Pengetahuan Barang Tekstil. Institut Teknologi Tekstil.

Noor Fitrihana. 2007. WUNY;Teknik Eksplorasi Zat Pewarna Alam Dari Tanaman di Sekitar Kita Untuk Bahan Tekstil. Yogyakarta: LPM UNY

Pemerintah Daerah DI Yogyakarta. 2002. Teknologi Pewarnaan Alam.

Rodia Syamwil. 2002. Pengetahuan Tekstil. Semarang.UNNES.

Rasyid Djufri. 1978. Teknologi Pengelantangan, Pencelupan dan Pencapan. Bandung: Institut Teknologi Tekstil.

Sewan Susanto. 1980. Seni Pengrajin Batik Indonesia Balai Penelitian Batik dan Kerajinan. Departemen Perindustrian

Suharsimi Arikunto.2006. Prosedur Penelitian, Suatu Pendekatan Praktek. Jakarta. PT. Rineka Cipta.

Tim Bina Karya Tani. 2008. Pedoman Bertanam Bawang Merah. Bandung: CV.Yrama Widya.

Wibowo Mordoko, dkk. 1975. Evaluasi tekstil Bagian Fisika. Institut Teknologi Tekstil.